Customization is our standard

With the foundation in our standard range, we have the ability to develop customized workstations based on detailed requirements. We have both the capacity and expertise needed to create unique solutions for each case, focusing on making your work more efficient.

Our design engineers have extensive skills in creating solutions with everything from unique features and custom dimensions to integration of your own or third-party products. Together with our resellers, we help you find the best solution – customization is our standard.

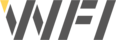

Idea / need

The first step in the process. An idea takes shape, a need arises, or an existing solution calls for improvement. Perhaps your vision is clear and concrete, perhaps it is simply a first thought on streamlining your workflow. To kick off the project and start creating your unique solution, it can be useful to test your idea or need in our configurator, The Yelper. Here, you can build a first base and send directly to us for an initial consultation.

Initial contact

At the first point of contact, it is important for us to gather as much specific information as possible about how the solution should function, be used, and look. If you still do not have a clear picture in mind, our experienced project team will guide you in the process forward, turning the idea into something that can move on to the design phase. These types of projects are often made in collaboration with our resellers with the relevant reseller engaged from the start.

Initial sketch

In most cases, we can deliver an initial sketch of your request quickly, usually within a few days after a clear specification and set of requirements have been provided. Our skilled design engineers work efficiently to provide a drawing proposal, which you can review and approve before we proceed with the process and issue a quotation.

In-house work

Once the quotation has been approved, the work continues in-house, with several departments involved, each playing a key role in keeping the process moving forward. The project team handles the creation of articles, our design engineers finalize all drawings, the purchasing department scans the market for suitable suppliers, and the warehouse prepares for any potential test assembly.

Ongoing dialogue

Throughout the process, there is of course, continuous dialogue between you as a customer and us as a supplier. Sketches and drawings may need to be revised and updated – for example, in response to new requirements, challenges, or ideas that arise along the way. We maintain a close collaboration to ensure the best possible conditions for a successful end result.

Potential prototype

In the final stage, a test assembly of a potential prototype may become relevant. In some cases, this is carried out on-site at our facilities to ensure functionality, performance, and design. In other cases, we produce renderings and drawings with the same purpose in mind.

Potential assembly

In addition to assembling a potential prototype, we also have the capacity to assemble the final product, either at our facilities or on-site at your location. Offering assembly as a service is a given for us, as we always strive to help others work smarter. Our skilled assemblers ensure that your products are up and running faster, while you do not have to worry about screws or assembly instructions.

Delivery

Time for delivery!

Follow-up

Some time after everything is in place, we always conduct a follow-up to check the current status. Are there any questions? Does the project need any additions? Do you have new ideas of further development? We review this together with the relevant reseller to ensure that the solution works as intended.

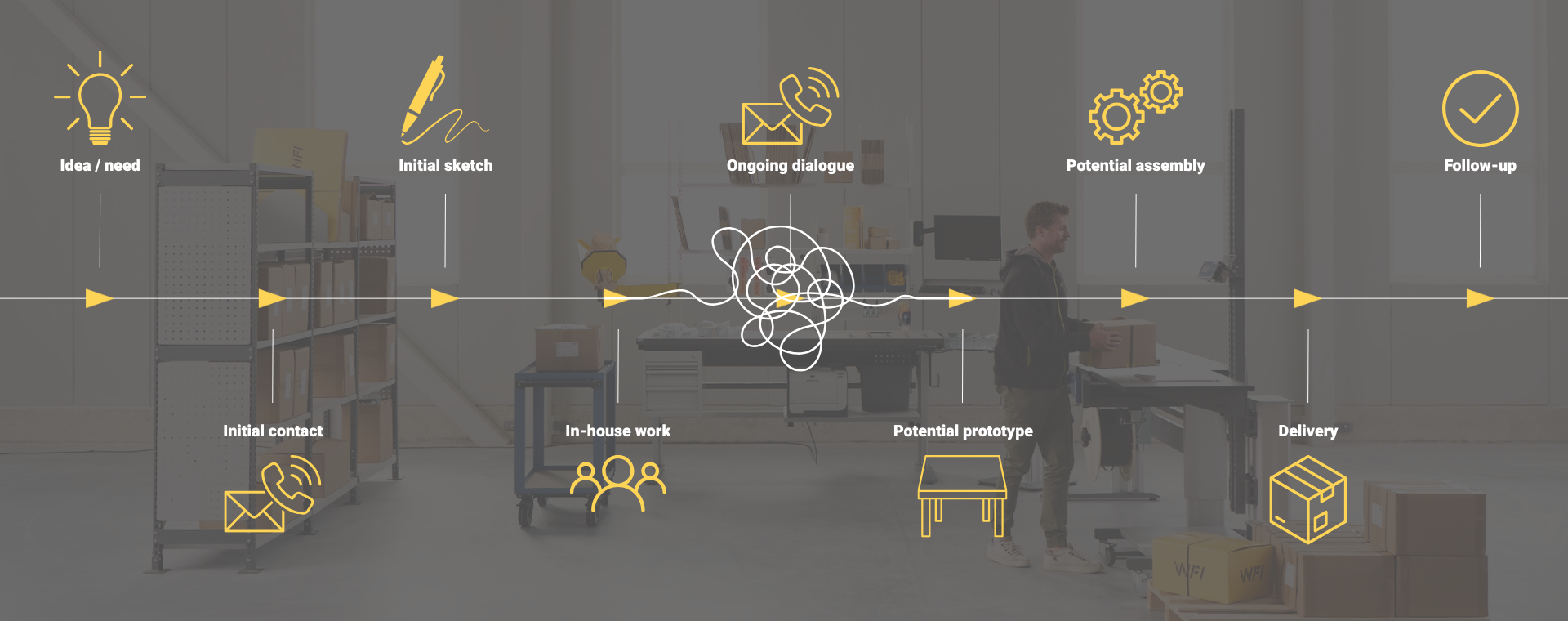

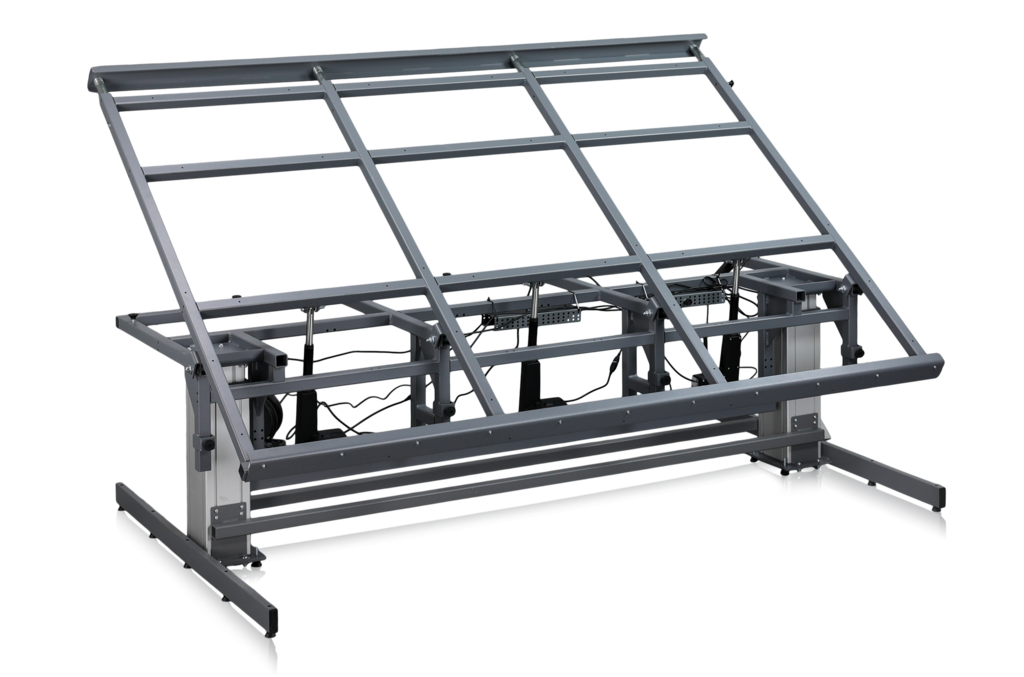

Example of a custom solution

Complete flow with third-party integration.

We have a quick in-house process for creating drawings and sketches for new projects and requests. But what I think is our main USP is our ability to customize and develop unique solutions for pretty much anything. As our standard range grows, so does our capacity in new areas – every article we have as standard can also be customized.

Customer cases for various industries and settings

Talk to our project team

Irene Melin / SALES PROJECTS

irene@wfiab.se

Erik Sandgren / DESIGN ENGINEER

erik@wfiab.se